Software development is where it’s at in large-format. So who’s doing what? Simon Creasy investigates.

Wide-format software providers have never had it so

tough. A decade or so ago some products, like Rips,

used to sell for as much as £2,000 – or more – a pop.

Today, users can choose to lease – sometimes for just

tens of pounds a month – or buy – for just a few hundred

pounds – a software solution that they can download

instantly from the internet with no training provided, or

indeed needed.

As a result, over the last few years the primary focus

of wide-format software companies has been to create

products that are cheap to buy and easy to use, which

ultimately leads to greater levels of commoditisation

and makes it increasingly difficult for developers to

make their offer stand out from the crowd. However, that

hasn’t deterred some software providers from trying.

Over the last few months a number of companies have

introduced innovative new levels of functionality to

existing products and launched brand new products to

meet customer demands.

Take the example of EFI. In December last year, it

released version 6.5 of its Fiery proServer, which was

specifically designed with the burgeoning textile market

in mind.

“The main focus was on the area of colour

management because in the textile market you have

quite a lot of different ink combinations and different ink

versions,” says Stefan Spiegel, general manager of EFI’s

Fiery wide-format print server/software operations.

To this end, EFI introduced Fiery Textile Bundle, to be

used with its Reggiani digital inkjet printers, which includes

new Fiery DesignPro Adobe Illustrator and Photoshop plugins and the latest Fiery proServer digital front end. Although

the first shipments of the product are still being bedded in,

EFI is already beta testing version seven, which launches this

month (April), just in time for Fespa.

“It’s a completely new development from our side

because it’s the first time we are going in the direction of

Fiery Command WorkStation [EFI’s print job management

interface],” says Spiegel. “We have approximately 1.5m

users of Command WorkStation and version 7 is going to be

the first time we are talking about what we are calling ‘one

Fiery’. That means you have a Fiery that can drive your toner

device and at the same time drive your inkjet devices.”

He says the introduction of this functionality, which

he describes as a “big step” for the firm, was driven by

customer feedback.

“When you go out to visit our customer base, if you

see a customer who is doing inkjet I am pretty sure you

will find a cutsheet in the office as well and vice versa.

When you go into shops customers are running a lot of

applications sometimes and that is getting more and more

complicated. This is the first time we can drive all devices,

including cutsheet, from one application.”

These changes have been largely driven by printers

trying to eradicate inefficiencies, according to Spiegel.

“Printers are coming more and more under pressure

because the square metre price is going down, so the

only way to keep their margin up and make money is to

speed up their machines in terms of set up and getting

data faster,” he says. “People are looking for easier

applications that can control their complete [print] shop.”

John Davies, product group manager, workflow, at

Fujifilm Europe, agrees. He says he has witnessed a

growing trend of print customers who are looking to consolidate the number of Rips they use.

“In the past what companies tended to do is they

would buy a new piece of equipment to fit a specific

purpose and it would come with a Rip from that vendor

– it could be ColorGate, Caldera or Onyx – and then very

quickly they would have six pieces of equipment in

house all with a different Rip and front end. What that

means is not everybody who works on that production

floor can use every piece of equipment to its most

efficient level.”

So what’s increasingly happening nowadays,

according to Davies, is customers are looking to

standardise their front end so that machine operators

can jump from different pieces of equipment and

this in turn helps to drive efficiencies. He sees the

current pressures and trends in the wide-format sector

following the same “efficiency pattern” that general

commercial print followed a decade or so ago.

“We go into a lot of wide-format companies and they

tend to just have a Rip on the front of a device and

everything that happens before it gets there is a very

manual process, which is just like the commercial print

world was 10-15 years ago,” he says. “But I think the

pressures are coming into the wide-format space as well

now, where there is a bit more competition so there is

a need to have a bit more automation and a bit more

efficiency. All of these things put together are driving

companies to think ‘we have the equipment, but we are

not using the print capacity that we’ve got efficiently’.”

He says one way wide-format printers are addressing

this capacity issue is through tools like the wide-format

automatic solution tilia Griffin, which was added to

Fujifilm’s suite of XMF workflow products late last year.

“Tilia Labs [the developer of tilia Griffin] already

had a product layout and planning tool for commercial

print, but they saw a need for a similar product in the

wide-format sector,” says Davies. “If you’re printing a

lot of irregular shaped items on the same material,

the question is ‘how do you maximise space and

squeeze it together on one sheet?’ What we found

some customers were doing was they were manually

doing this using InDesign or Illustrator. It was literally

someone’s job to take all of these jobs in – 50 of

these items, 20 of these and 30 of these – and then

drag and drop them and arrange them on the sheet,

whereas Griffin will do that automatically and work out

the most efficient way of printing it. That can turn a

couple of hours of manual work into 10-15 minutes

within the application.”

This automation of processes that might historically

have been dealt with manually is a growing theme from

customers who are trying to optimise the way they

operate.

“Automation and efficiency is where people look to

first when they are getting squeezed on price,” says

Davies. “How do I get more out of what I’ve got without

taking on more people or buying more equipment? It’s

looking back and saying ‘this machine is only printing

two hours a day and we have a seven hour day in our

business’. Or some customers might say ‘we are quite

busy all day, but we are not printing all the time, so

how do I make my operation more efficient up front so

that when the jobs come in they go quickly from being

booked in by the customer service person to being ready to

be printed on the shop floor’?”

“Automation is everywhere” at the moment, says Jonathan

Rogers, international marketing manager at Onyx Graphics

“Customers are asking for tools that increase production

automation and output capacity, reduce manual error and

have the means necessary to prove superior prints to their

customers in a simple manner,” he explains. “PSPs are

looking for ways to cut costs and reduce errors in the print

shop and are looking for automation to help. Wide-format

printing is inherently complex and not always straightforward

to automate. This is an area we see growing in demand.”

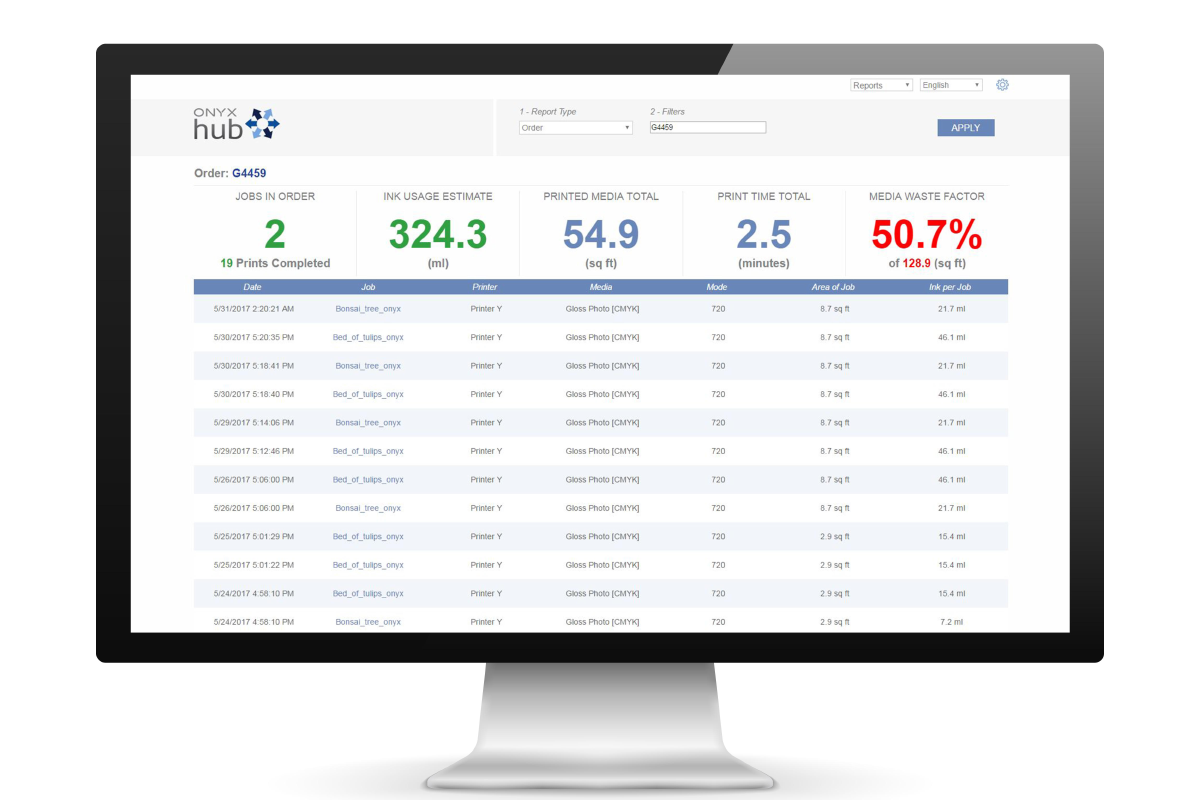

At Fespa 2018 Onyx will be showcasing the latest release

of Onyx Hub, which features real-time and historic trend data,

including ink usage and media waste, as well as actual costs

for ink, media, printer and labor rates for job costing.

“These new features help business owners and production

managers answer questions such as ‘did we estimate that

job correctly?’ and ‘did we make any money on that job?’,”

says Rogers. “Onyx Hub also helps eliminate inefficiencies in

production workflows and drill down from site-wide data to job

level to delve into business needs such as printer utilisation,

production bottlenecks, training needs, and more.”

PSPs are at different stages of digital transformation, but

there are some commonalities across all businesses and this

has played a large part in influencing the latest iteration of

products brought to market by software providers, according

to Arnaud Fabre, product manager at Caldera.

He adds that “agile” print shops are eager to source

products that offer “differentiation and high added value

propositions” and that many of the features added to Caldera’s Rip software version 11.2, which was released

in February, were in direct response to customer

demands.

“They wanted more help to master the software,

so we integrated direct help access links per module

and views through HelpLinks; they wanted help with

media savings for special applications where the media

is textured and so orientation really matters, so we

added ContourNesting 180°; they wanted a flexible

and common interface to manage multi-layer printing to

print special effects, so we introduced MultiLayer; and

they wanted to have the ability to handle the optical

brightness on all they media they manage – either

opaque or transparent – so we added TotalColor qb,”

says Fabre.

Likewise HP has launched a number of products

responding to the needs of customers, says Phil Oakley,

large-format business manager UK and Ireland at HP

“Last November, we partnered with award-winning

designers, the Yarza Twins, Silas Amos, and Smirnoff

to launch the beta programme of HP SmartStream

Designer for Designers (D4D),” says Oakley. “The

new SmartStream D4D software is a suite of design

solutions that enable designers to create up to 20

variations on any design, and to take control of their

own creative process.”

Over the course of the last 12 months HP has also

expanded its HP Click Software for use on all DesignJet

T-Series machines “in response to the demand we were

seeing for an accessible, low-maintenance printing

experience. With no need for a driver, the software

offers easy, simple one-click printing, plus drag and

drop multipage PDF printing and real-print preview, while

optimising media usage and costs,” explains Oakley.

Going forward there are a number of areas where

software providers think there is scope for further

product innovation and growth. One is Cloud-based

software.

“Everything to do with Cloud processing and Cloud

colour management is a big, big topic,” says EFI’s

Spiegel. “The people in the shops are really looking

for help and that is coming from the Cloud. It’s a big

trend that we see more and more of and we are trying

to address this. I’m not sure if we will do something on

this for Fespa [this year], but it’s clearly something for

the future.”

It is something Rip provider Shiraz Software is already

focusing a lot of its efforts and energies on, according

to the company’s business development director Ramin

Shahbazi. He says Shiraz has created some “exciting

stuff” to capitalise on this growth area.

“One of the things we have is an end-to-end Web-toprint

solution,” explains Shahbazi. “So we create the

front end, the middle ware and we have the back end

– the server – and it is all fully integrated. At the moment

if a job is submitted via ecommerce then what tends

to happen is the customer has to prepare the job then

they send it to the Rip to be printed. We’ve effectively

eliminated that process – it is all automated.”

A potentially even more exciting opportunity that Shiraz

has identified is the introduction of “image streaming”

technology.

“It’s similar to Spotify, where you stream music without

giving the files away,” says Shahbazi. “Well we can stream

images without giving the files away to the production

site.” He says the company has developed a streaming

technology that allows it to “securely and transparently”

stream images for printing.

“Take the example of a website that offers artwork.

The user can select the piece of art they want to print

online, but the job doesn’t go to the printer with the image.

The image gets streamed at the time the job is being

produced from a very secure Cloud storage. We have a lot

of technology that protects that image so it can’t be saved

and it can’t be hacked.”

This is an area where he thinks a lot of innovation and

software development could occur in the future as artwork

and designs potentially become more valuable than the

print itself – especially in markets like home furnishings,

which he thinks will become much more digital print

orientated.

“I haven’t been this excited about this part of the market

for many years,” says Shahbazi. “It’s been the same old,

same old, whereas now I can see an area where we can

add a lot of value to someone who is looking for a solution

like that.”

Products that add value is what customers are

increasingly on the lookout for at the moment, so you can

expect to see further innovation from software providers in

these emerging niche areas, in addition to solutions that

help to drive print shop efficiencies, in the months ahead.