Richard Stuart-Turner reports on the latest hardware developments in the thriving digital textile printing market.

Constantly talked up over the last few years as one

of the most promising areas of large-format, digital

textile printing requires little introduction. The sector is

experiencing major growth – particularly in the areas of

soft signage, fashion and home textiles – as the demand

for personalised goods continues to take hold, and there

is no sign of things slowing down.

According to Smithers Pira, a total of 870m m2 of fabric

were printed on digital equipment in 2016 – worth $1.29bn

(£940m) – and this volume will increase at an average

annual rate of 17.5% in the years up to 2021, consuming

nearly 1.95bn m2 in that year and equating to a market

value of $2.66bn.

With such a positive outlook for the market, the most

recent European Fespa show, held in Hamburg last May,

was unsurprisingly awash with new textile technologies and

we can expect to see another raft of developments at the

2018 event, which will take place at Messe Berlin from 15

to 18 May.

As a warm-up of sorts, January saw the 2018 version

of Heimtextil, the international textile and garment

manufacturing trade fair held annually in Frankfurt. While

new printer launches at the show were thin on the ground,

there were plenty of hints as to where the market is

heading.

HP had one machine running on its stand – the Latex

570 – but the company made a conscious decision to focus

less on hardware this year.

“We were trying to move away from showing the

oven – it’s more important to show what comes out of it,

and so our Heimtextil stand was really about showing

applications,” says HP business development manager

for printed decorative applications, Terry Raghunath.

HP has continued to update its Latex portfolio,

adding two mid-range 3.2m-wide options in the past

few months – the Latex 3600 and 3200. Both machines

are able to print textiles and canvas at speeds of up to

44m2/hr.

“The textile market is a huge opportunity and whoever

is not sniffing there is probably missing the point. Our

Achilles heal has always been the washability with the

inks, but there are more and more textile materials that

we can start to use now,” says Raghunath.

“The Latex technology has been gaining a lot of

awareness and has become a reference on the market,

so as it has been gaining more penetration, media

manufacturers have been waking up to the fact that they

need to develop media for this technology – we’re seeing

this in wallcoverings, window blinds and many other

applications that we’re going after.”

The company will also broaden its textile printing

horizon in the coming years, according to Mike Horsten,

HP Graphics Solutions Business EMEA sales manager

for large-format graphic production. “There is a very high

push from our senior management to open up textiles

beyond Latex,” he says. “Today our focus is Latex, which

is going to protect us for the long-term, but there will be

different technologies coming online.”

HP was running wallcovering printing demos on its Latex 570 at Heimtextil and was far from the only

exhibitor concentrating on this area. Industrial Inkjet

(IIJ) for instance, used the show to update wallpaper

manufacturers on its digital wallpaper printing system,

following more than two years of R&D with partner Konica

Minolta.

The firm says this system will compete with

conventional printing methods in terms of productivity and

cost-per roll and can print on media including paper, PVC

and non-woven – coated and uncoated – at high speed.

There are no restrictions on image length and mural-wall

images can be printed back-to-back without a gap.

Mimaki showed a range of kit at Heimtextil, including

its Tx300P-1800 – highlighting the machine’s dual ink

capability by demonstrating both dye-sub onto polyester

and pigment onto natural fabrics using the same device.

It also demonstrated the Tx300P-1800B, showing how

the belt option adds the stability needed for printing onto

stretch and lightweight materials.

“The advancements that Mimaki has made over the

last few years has ensured that print quality and speeds

are constantly improving. Another major development

is that we are consistently seeing running costs coming

down,” says Brett Platt, textile product manager at Mimaki

distributor Hybrid Services.

Platt says one of the main reasons the home textile

market is growing so quickly is recent advancements in

pigment ink technology.

“Historically, natural fabrics could only be printed with

reactive inks, which require steaming and washing to

finish. However, advanced pigment ink technology only

requires heat to fix and the process is far easier. From an

investment point of view, the development of pigment inks

have meant that you don’t need a factory with a steamer

or a wash line to produce high quality textiles.”

Furthermore, Platt adds advancements in polyester

fabrics are enabling PSPs to more easily branch out into

the production of soft signage, sportswear and home

interiors with an entry-level sublimation transfer printer.

“Making the transition into sublimation transfer printing

is an easy move as the media handling of transfer paper

is very similar to that of general signage substrates.

The handling of natural fabrics is more complicated than

transfer paper, however Mimaki machines such as the

Tx300P-1800B are designed to keep media stable.”

High on Durst’s list of priorities is the continual

development of its Alpha Series printers and Alpha Ink P,

the one-step pigment ink it has developed especially for

these machines.

“Standard materials such as cotton and polyester

do not require pre- and post-treatment with this ink, so

the entire digital production process is accelerated and

simplified,” says Durst textile printing segment manager,

Martin Winkler.

“The Durst Alpha Series features different

configurations and print widths for industrial printing

of fashion garment and apparel, home textiles and

upholstery. This efficient and economic digital textile

production has step-less quality up to 1,450m2/hr.

At Fespa last year, Durst marked the European show

debut of its 3.2m-wide Rhotex 325 printer, which Winkler

says has been “extremely well received in the market”.

“One of its incredible benefits is featuring the dual properties of direct-to-textile and printing on transfer paper.”

For PSPs looking to print wider, a significant recent

development came from ATPColor, which last year debuted

what it claims is the world’s first 5.3m-wide grand-format textile

printer with integrated inline fixation. This one-step process

means users do not need to load and unload both the printer

and the calender.

Meanwhile, EFI’s latest superwide-format textile addition is

the 5.2m-wide Vutek FabriVu 520, which incorporates Reggiani

technology. This machine can print at up to 446m2/hr, with a

resolution up to 2,400dpi, and is suitable for producing items

including banners, flags, backlit displays and wall murals. EFI

says it can handle both direct-to-textile and transfer printing with

an easy changeover using the same inkset.

More recently the manufacturer, which showed printed

samples rather than machinery at Heimtextil, has launched the

smaller Reggiani Renoir Flexy, a 1.8m-wide machine capable of

printing at up to 400m2/hr with a resolution of up to 2,400dpi.

This printer can handle fabrics ranging from knitted to woven as

well as low- and high-stretchable materials.

“The Flexy can be used for sampling and small production. It

was created for the entry-level segment of the garment market,”

says EFI Reggiani sales and marketing director, Michele Riva.

EFI has also just launched its Fiery Textile Bundle, a set of

design and production workflow innovations for the Reggiani

machinery. The bundle includes new Fiery DesignPro Adobe

Illustrator and Photoshop plug-ins, to enable users to create

professional textile designs efficiently, as well as version 6.5 of

the Fiery proServer digital front-end.

The company says version 6.5 is an advanced offering for use

with wide- and superwide-format printers that offers high-quality

textile production, with support for multiple ink types and colour

technology and the production tools to handle step and repeat,

changes in fabric dimensions during production, and brand

colour accuracy.

“In 2018 we have a roadmap where we will have new

developments in equipment, in chemistry and in the depth of

applications possible. In terms of products, we will continue

our developments in pigment because this is an area where we

believe there is huge potential,” says Riva.

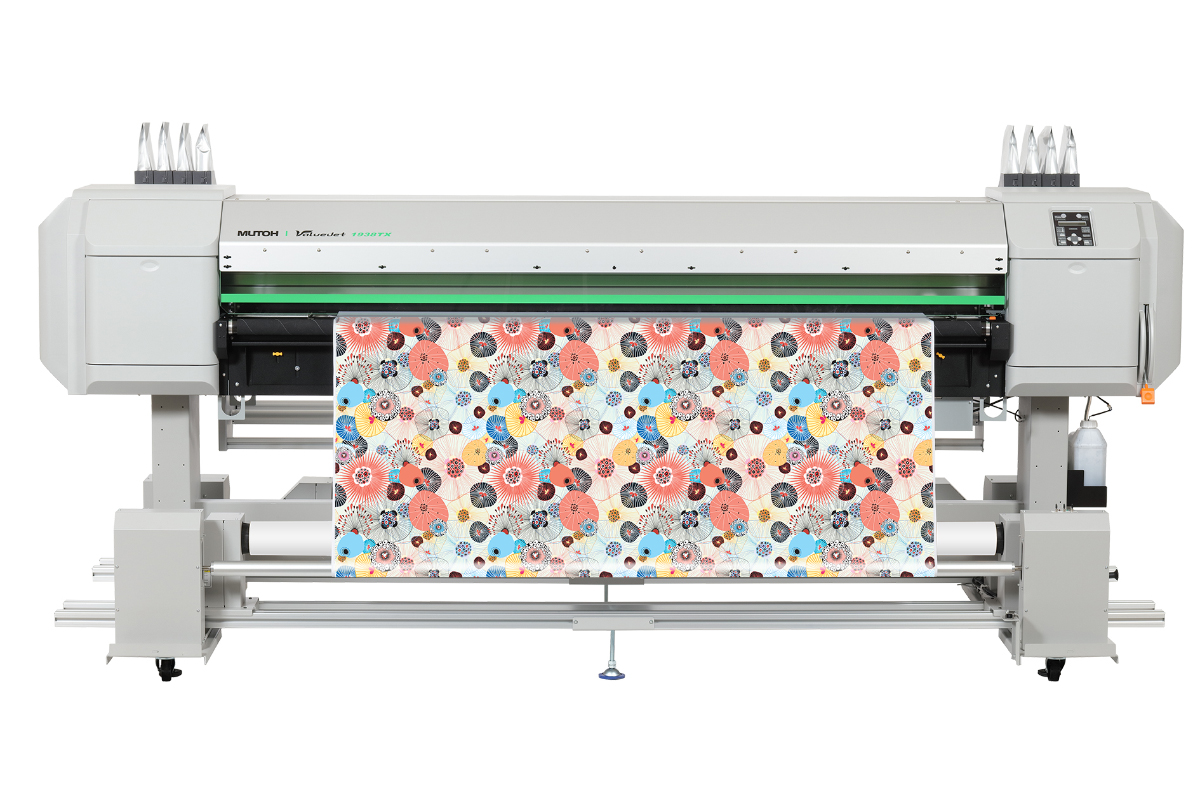

Mutoh showed its ValueJet 1938TX and 1948WX models at

Heimtextil. The 1938TX is a 1.9m-wide direct-to-textile printer that can print on closed and open non-stretch and limited

stretch fabrics while the 1948WX is an industrial highquality

1.9m-wide dye-sub printer.

The 1938TX incorporates a newly engineered high-end

fabric feeding, tensioning and take-up system which Mutoh

says guarantees “worry-free” feeding and transport of

fabrics.

Mutoh commercial marketing manager, Nick Decock,

says the environmentally friendly nature of textile printing

particularly appeals to PSPs and their clients. “The lower

production cost versus analogue technologies – no setup

cost, even for one-offs – and the environmental comfort

– there is no need to clean plates after printing – makes

digital print equipment environmentally friendly.”

On the smaller side of the digital textile printing market

are the direct-to-garment printers that are generally used

for producing promotional items such as t-shirts, hoodies

and sweatshirts – add-on applications for so many largeformat

PSPs and worth a look here because of that.

Kornit Digital’s recently launched Storm Duo, which

runs at a maximum speed of 190 garments per hour, is

targeted at light fabric printing, while the company’s Vulcan

can print 250 light or dark garments per hour and is

developed for mass production and customisation.

While this kit may be ideal for screen printers

considering a move to digital, or those dealing with high

volumes, there are plenty of alternatives available for PSPs

producing shorter runs or just getting started in this area.

Ricoh has just entered the direct-to-garment fray for the

first time with two new printers, the Ri 3000 and Ri 6000.

These machines, which use Ricoh’s water-based pigment

ink, print at speeds of up to 27 seconds per garment.

“The demand for decorated garments is expected to

continue to grow as it becomes easier to create and order

these items,” says Ricoh Europe head of commercial inkjet

business, Graham Kennedy.

“The textile print market is changing – the main

important trends are to be able to deliver fast and with

no minimum order quantity. This drives the demand for

digital print solutions rather than conventional analogue

technologies.”

Epson’s direct-to-garment printer the SureColor SCF2000,

which prints onto a wide range of cotton or cotton

blend products, is well established on the market. The

company says its future developments in this area will

focus on more automated maintenance and a lower cost

of ownership.

“In this Industry 4.0 era people are always looking

for more intelligent systems where operators are there

to confirm quality, rather than be the critical element to achieve quality,” says Epson Europe market development

manager, Heather Kendle.

The SC-F2000 was on Epson’s Heimtextil stand along with

the Monna Lisa Evo Tre 650m2/hr industrial textile printer

and the first showing in Germany of the company’s new

SureColor SC-F9300 dye-sub printer.

Kendle says the SC-F9300 is designed primarily for fast,

high-volume printing for clothing, textiles and soft signage, as

well as other printed merchandise.

“For the first time Epson has taken its Precision Dot

technology into its dye-sub products including a halftone

module, look-up tables and micro-weave, helping to make an

instantly noticeable difference to print quality, and make it

easy to get quality results straight out of the box.

“Furthermore, Epson’s wide gamut CMYK input profile

combines with UltraChrome DS inks to ensure the maximum

possible colour gamut, for accurate reproduction of even the

most complex designs.

“It operates at up to 108.6m2/hr and is a completely

Epson solution, comprising printer, inks and software, that

maximises uptime, with improved take-up and other reliability

features to eliminate common industry problems such as

cockling and head strikes.”

Heimtextil served to highlight the multitude of applications

that are now possible with digital textile printing and

Fespa in Berlin will likely build on that in May. Textiles is

set to dominate the agenda once again and the printer

manufacturers will start to show their hands over the next few

weeks, so watch this space closely.